What is PLC Programming in Industrial Automation?

Programmable logic controllers, more commonly known as PLCs, are at the heart of modern industrial automation. They keep production lines moving, support safety systems, and ensure that machinery behaves exactly as it should. Although the term is familiar within the engineering world, many people outside the industry are not fully aware of how PLC programming works or why it is so important. Understanding the basics can help businesses to appreciate the value of a well-designed plc control panel and the expertise behind it.

What does PLC do?

A PLC is a robust industrial computer designed to monitor inputs, make decisions, and control outputs. In simple terms, it acts as the brain of a machine or process. Unlike a traditional computer, a PLC is built to operate in challenging environments where heat, vibration, and electrical noise are common.

PLCs receive signals from sensors, switches, and other field devices. They then process this information using a programmed set of instructions and send commands to actuators, motors, valves, and other equipment. Everything happens in real time, which is essential for maintaining smooth and safe operation.

For automation control panel manufacturers, integrating PLC technology allows them to deliver systems that can automate even the most complex industrial tasks with accuracy and reliability.

What is the role of PLC programming?

PLC programming is the process of creating the logic that tells the controller how to behave. This is done using programming languages such as ladder logic, function block diagrams, or structured text. Each language has its strengths, but all serve the same purpose, which is to map out the sequence of events that make up an automated process.

For example, a PLC could be programmed to start a conveyor belt when a photoelectric sensor detects a product. It could also trigger alarms if a temperature limit is exceeded or put machinery into a safe state when an emergency stop button is pressed.

Good programming takes into account not only the normal running conditions but also what should happen during faults, shutdowns, or changes in production. Skilled programmers build systems that are both efficient and resilient, ensuring that processes continue running smoothly even when conditions vary.

Why are PLCs used across so many industries?

PLCs became popular because they are flexible, easy to update, and far more reliable than the old relay-based systems that once dominated factories. A single PLC can control multiple machines, scale with growing production needs, and provide detailed diagnostics that help engineers respond quickly to issues.

Industries such as food processing, packaging, manufacturing, and water treatment all rely heavily on PLC systems. The technology allows processes to be automated with precision while maintaining traceability and consistency.

For companies using bespoke equipment, a plc control panel makes it possible to adapt the logic to suit unique processes or custom machinery. This is where experienced automation control panel manufacturers add significant value by ensuring the hardware and software work together seamlessly.

How to integrate PLCs within control panels

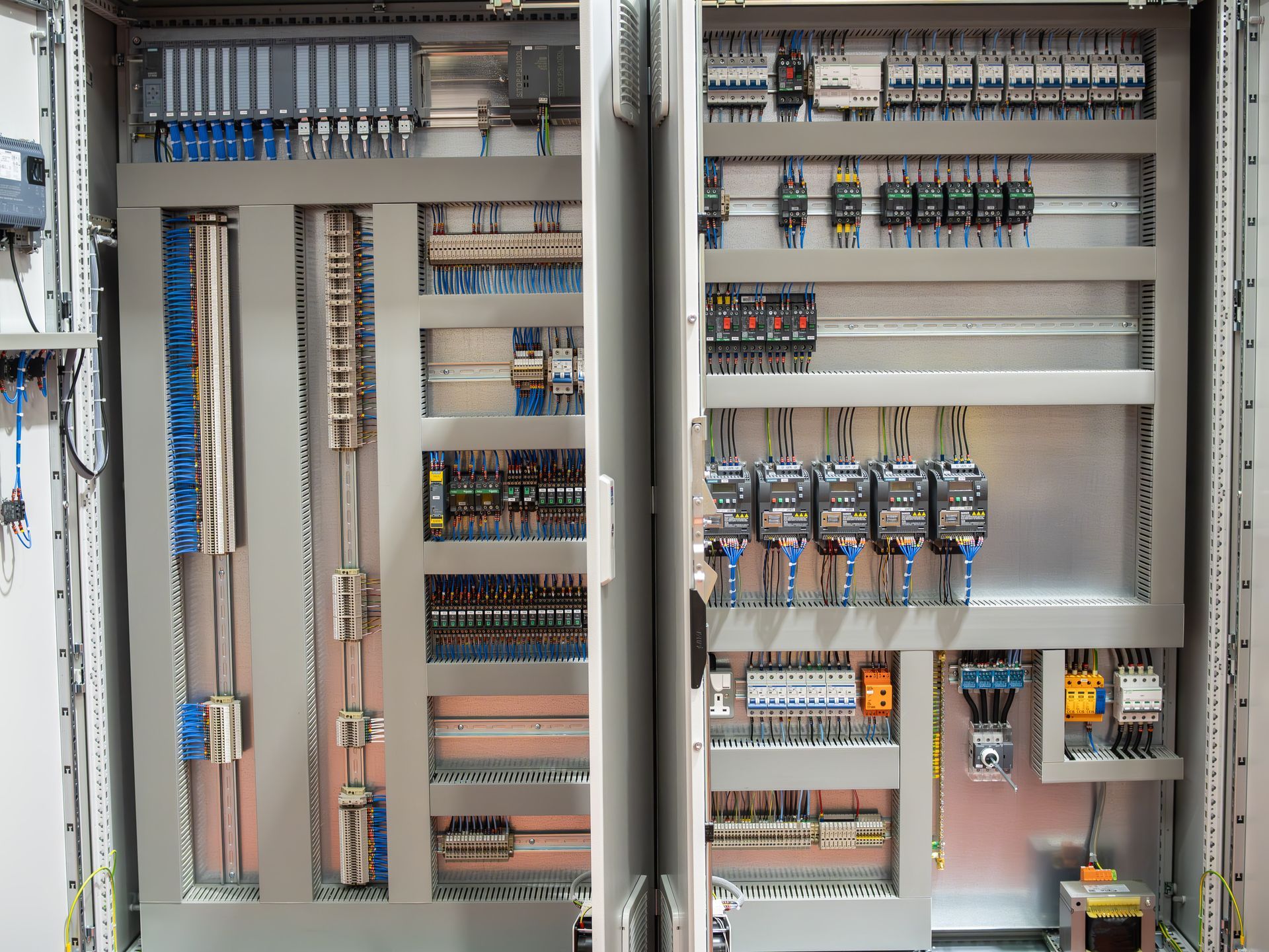

A PLC does not operate alone. It must be integrated into a wider control system that houses wiring, safety components, communication modules, and power distribution. A well-built control panel ensures that the PLC can communicate effectively with all connected devices and that the system complies with safety and regulatory standards.

Manufacturers must also consider layout and accessibility. Clean wiring, labelled terminals, and clear documentation make maintenance easier throughout the life of the system. This level of detail helps businesses avoid unnecessary downtime and supports long term reliability.

What is the future of PLC programming?

PLC systems continue to evolve. Modern systems now support advanced communication networks, remote monitoring, and data analytics. This means PLCs are not only controlling processes but also collecting valuable information that can help improve efficiency and reduce energy use.

As automation becomes more intelligent, the role of skilled programmers and automation control panel manufacturers becomes even more important. They ensure that systems are designed with both current needs and future expansion in mind.

PLC programming is a cornerstone of industrial automation. It turns electrical hardware into a fully functioning, intelligent system that can carry out complex tasks safely and efficiently. Whether used in small workshop machinery or large-scale production lines, PLCs support reliability, productivity, and long-term performance.

FAQS

What does a PLC do in an industrial environment?

A PLC functions as the central brain of a machine or process. It receives signals from sensors and switches, processes this information using programmed instructions, and then controls outputs such as motors, valves, and actuators.

What does PLC programming mean?

PLC programming involves creating the logical instructions that determine how the controller behaves. Effective programming ensures efficiency, consistency, and resilience.

Why are PLCs used across so many industries?

PLCs are reliable, flexible, and easy to update, making them ideal for diverse sectors such as food processing, packaging, manufacturing, and water treatment.

How are PLCs integrated within control panels?

A PLC operates as part of a wider control system housed within a dedicated panel. This panel includes wiring, safety components, communication modules, and power distribution.