MATERIALS HANDLING

CASE STUDY

Efficient Materials Handling for Assembly

CHEMICAL PROCESSING CASE STUDY

THE CHALLENGE

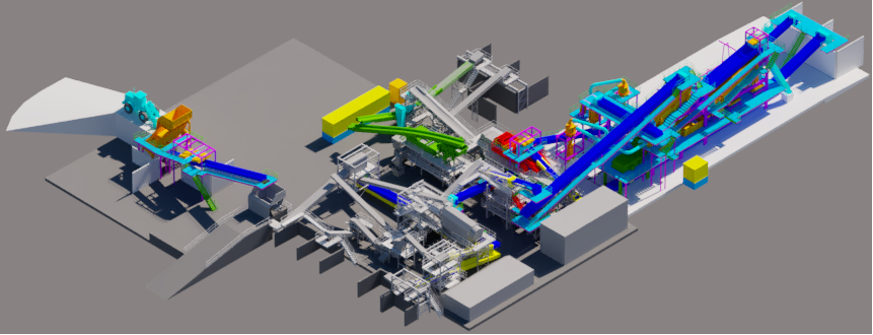

The complete design and electrical installation of a plastics manufacturing facility. The project comprised of the relocation of existing manufacturing lines from the client’s site in Cinderford to their site in Oldbury Birmingham.

THE SOLUTION

The work consisted of disconnection of both mechanical and electrical controls, carrying out the re installation of these at the Oldbury site and ensuring that all services were provided.

Associated works included electrical design changes on the extruder lines, the integration and control of a vacuum conveyor system for the plastic material, design and installation of a 2MVA transformer and HV switchgear panel.

The client also required ATEX compliance for which we were able to organise and obtain the necessary certification.

THE VALUE

S M Control Engineering also handled all the mechanical & civils engineering works. These items included bunded transformer bases, equipment/plant platforms and 2 off material silos.

If you have any materials handling requirements (including control system and electrical panel construction), please feel free to contact us or call us for a consultation on (01922) 725956 or email us at sales@sm-control.co.uk