CHEMICAL PROCESSING

CASE STUDY

Enhancing Efficiency in Chemical Processing Solutions

CHEMICAL PROCESSING CASE STUDY

THE CHALLENGE

S M Control Engineering Ltd carried out the design, assembly, installation and commissioning of a complete control system for a Chemical Production Facility.

THE SOLUTION

The control system was responsible for:

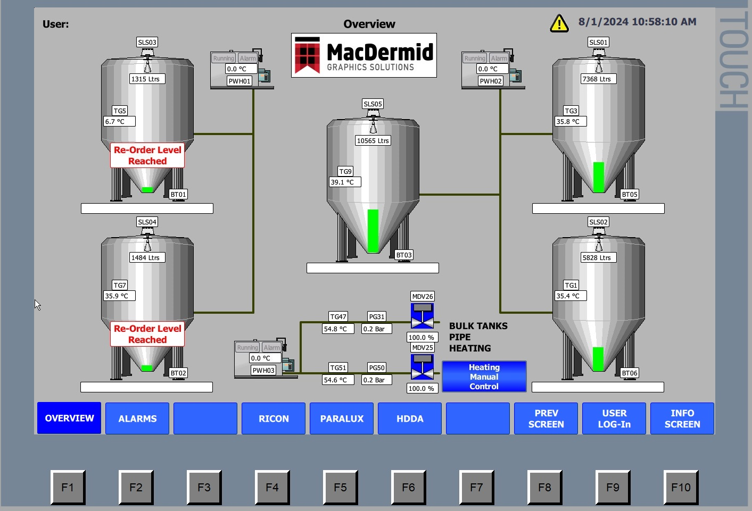

- Intake control & monitoring of Bulk Raw Material from Tankers.

- Control & monitoring of Bulk Raw Material Temperatures.

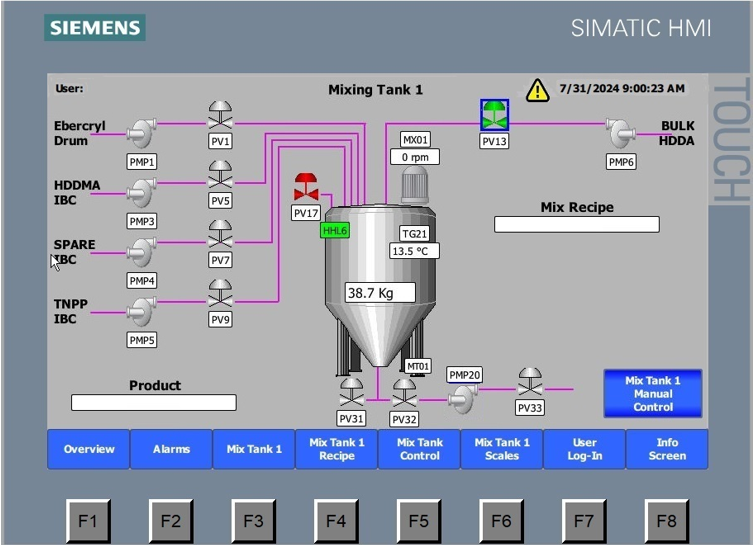

- Monitoring of Raw Materials from IBC.

- Monitoring of Minor Additives and Raw Materials from other sources.

- Blending of required mixes based on formulae including Raw Material quantities, temperature & mix control.

- Quality Control & rework of completed mixes.

- Control of transfer of completed mixes to Holding & Day Tanks.

- Control of transfer from Holding Tanks to Day Tanks.

- Monitoring of Holding & Day Tanks levels.

- Interface with Extruder Control System.

THE VALUE

The design of the control system is such that critical failures and incorrect setup prevents control from taking place and stops control in a safe and controlled manner.

If you have any chemical handling requirements (including control system and electrical panel construction), please feel free to contact us or call us for a consultation on

(01922) 725956 or email us at

sales@sm-control.co.uk