PLC / SCADA SYSTEMS

Scada (Supervisory Control and Data Acquisition) and PLC (Programmable Logic Controllers) play an important role in a manufacturing process and

increasing productivity.

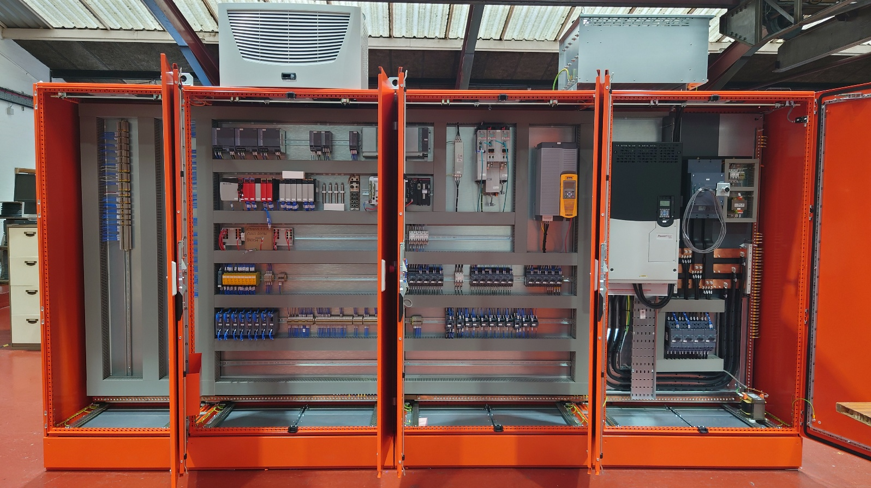

PLC AND HMI CONTROL SYSTEMS

PLC (Programmable Logic Controller) control panels play a crucial role in the efficient functioning of a plc control system. The design of these control panels is a complex process that requires a thorough understanding of the industrial process being controlled and the requirements of the plc control system.

PLC CONTROL PANEL DESIGN

Systems Integrators such as S M Control Engineering offer comprehensive services for the design of PLC and HMI based control systems. The design process begins with the identification of the specific requirements of the industrial process from a client URS, FDS or a general specification which will determine the PLC and HMI hardware needed for industrial process.

One of the key benefits of working with S M Control Engineering is their focus on the most cost-effective solution for the clients that is affordable but without sacrificing quality and reliability.

In addition to ensuring a cost effective solution, S M Control Engineering also place a strong emphasis on safety during design of the complete system, using where necessary safety PLCs or a providing dual redundancy system.

PLC and HMI software is designed to keep not just the process requirements in mind but also to provide ensure that operators cannot override any safety issues through mal operation of the system.

S M Control Engineering offer a turnkey service for the design, build, installation and commissioning for all control systems comprising of PLC’s and HMI units.

We work with all these major PLC and HMI hardware manufacturers:

Siemens Rockwell Schneider Mitsubishi Omron

MACHINERY DIRECTIVE 2006/42/EC

CE MARKING 93/68/EEC 93/465/EEC

UKCA MARKING FOR PRODUCTS SUPPLIED IN THE UK

LOW VOLTAGE DIRECTIVE (LVD) 73/23/EEC

EMC DIRECTIVE 2004/108/EC

HEALTH & SAFETY AT WORK ACT 1974

S M Control offer a complete turnkey solution for PLC/HMI control systems which is a key benefit of when integrating all components such as selection of the equipment, electrical design, software, installation and commissioning on site. Each control system is comprehensively tested at our works, with clients invited to attend witness testing (Factory acceptance Tests), against the agreed specification or functional design specification (FDS).

In conclusion clients can consider with confidence that S M Control Engineering will provide them with the most comprehensive solution along with a commitment to ensuring the complete

SCADA ENGINEERED SOLUTIONS

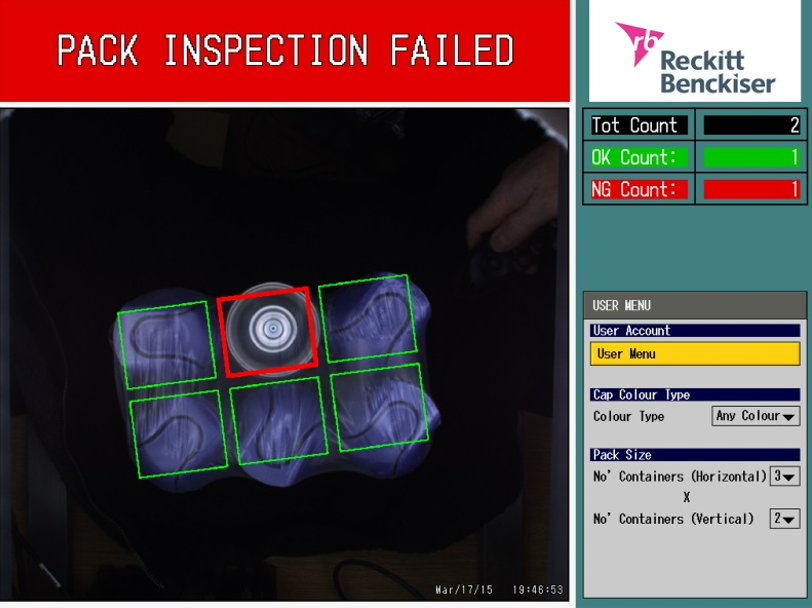

SM Control Engineering is a leading provider of automation and control systems, offering comprehensive SCADA (Supervisory Control and Data Acquisition) solutions for a diverse range of industries such water, chemical and mechanical handling. Our team of experts provides the complete SCADA system design, and solutions that are specifically tailored to meet the needs of these industries.

SM Control’s SCADA systems provide real-time monitoring and control of industrial processes, enabling facilities in these industries to operate more efficiently and effectively. The systems are designed to be user-friendly, making it easy for operators to monitor and control processes in real-time.

In addition to real-time monitoring and control, SM Control’s SCADA systems also offer a range of security features to protect against unauthorised access. SCADA systems are also used to log and store process data over long periods for analysis.

SM Control is dedicated to providing their customers with high-quality, reliable SCADA systems that meet their specific needs and requirements.

In conclusion, SM Control should be considered for SCADA systems for automation and control systems in all industries due to their experience and expertise in providing comprehensive SCADA solutions. Our focus on real-time monitoring and control, makes us a reliable and trustworthy partner for industrial facilities in these industries.

S M Control specialises in the design, build, and integration of custom SCADA systems for a broad range of industries and applications, including water/wastewater, food and beverage, Bio-tech, Materials handling, Plating lines and more. Our engineering team has experience in implementing PLC-based SCADA solutions and can provide full project services, including system planning and analysis, hardware and software configuration, PLC programming, communication network design and integration, commissioning, documentation, troubleshooting, and maintenance.

SCADA SYSTEMS APPLICATIONS

S M Control Engineering design, build and integrate SCADA systems on any of the industry-leading software platforms, including Rockwell Factory Talk, Siemens WinCC , Aveva (Wonderware) Systems Platform, Mitsubishi and many more. Our experience with these platforms gives us the ability to make qualified recommendations on the right system to match your requirements and objectives.

We develop supervisory control software with well-structured code to simplify future feature additions and updates. Our software is designed with ease-of-use in mind, which results in clean and consistent interfaces that reduce operator errors and help you focus on the important information. Our Engineers are experienced in:

- Compilation of a Functional Design Specification (FDS) documentation

- Remote telemetry & communication network integration

- Configuration of menus, sequences, tags and alarms

- Historian, database configuration, and management

- SQL database set up for time and date stamp information

- SCADA and PLC upgrades automation upgrades to existing plant process

- Setting up of remote access equipment such as EWON units to provide plant information and alarm data direct to a mobile or by email

- Reporting and Trending

- Commissioning, training, and maintenance