AEROSPACE

CASE STUDY

Aerospace components for your company

AEROSPACE CASE STUDY

THE CHALLENGE

Major Component Producer for the Aerospace Industry

S M Control Engineering Ltd carried out the design, assembly, installation and commissioning of a complete control system for a chemical treatment and plating line.

THE SOLUTION

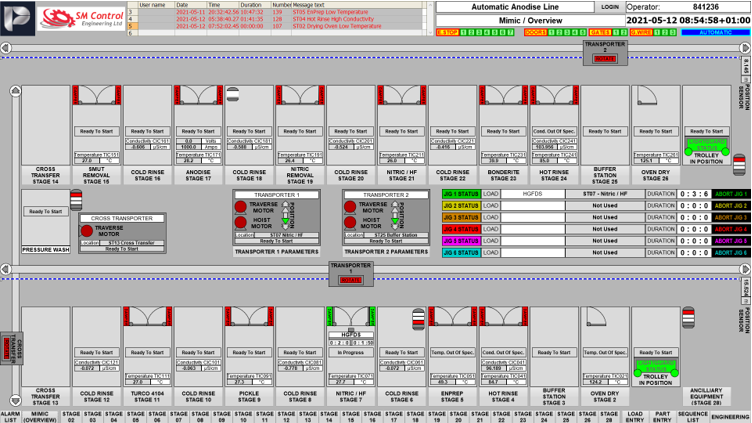

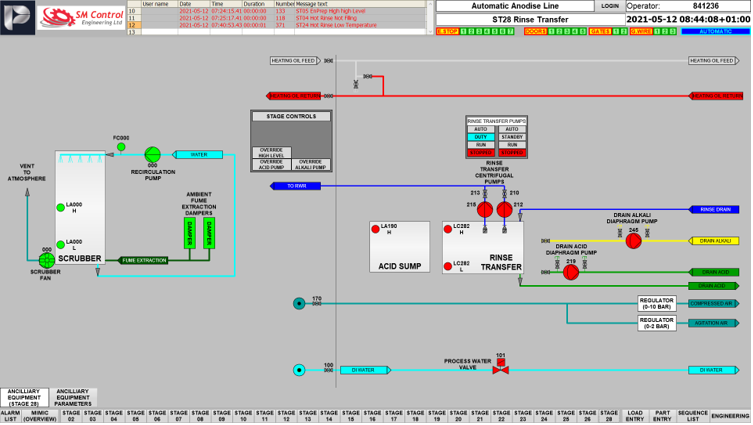

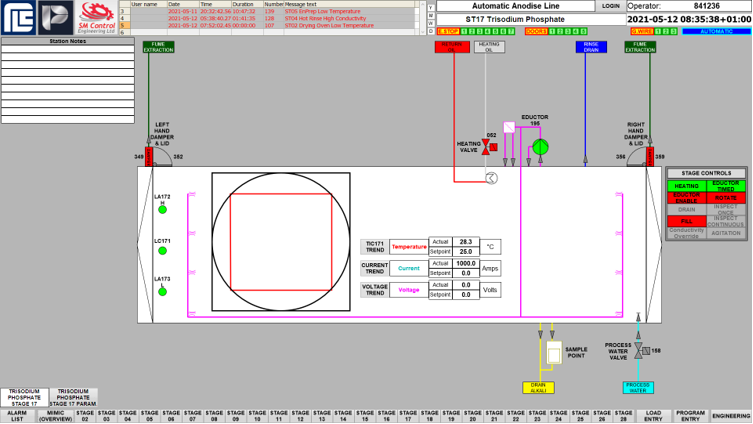

This line took high precision machined parts made from titanium, and via a system of complex motorised jigs (flight bars) and overhead mobile cranes (transporters) transferred them between chemical tanks, rinse / wash tanks and plating tanks to carry out critical processes.

The system was designed to handle up to six flight bars simultaneously across twenty-four tanks and three transporters. Controlled parameters included tank fluid levels, chemical strength, pH, conductivity and temperature. Electro-plating was carried out by rectifiers capable of currents up to 800A, which had to be monitored and controlled throughout the plating process.

The progress of each job through the plating line was monitored, recorded and documented automatically by the system.

THE VALUE

Ancillary equipment included a water treatment plant to process tank run-off. and an air extraction and scrubber system, both to remove / neutralize harmful chemicals.

If you have any aerospace control system requirements (including electrical panel construction), please feel free to contact us or call us for a consultation on

(01922) 725956 or email us at

sales@sm-control.co.uk