Risk Assessment for Electrical Control Systems

Electrical control systems are at the heart of modern industry. They regulate machinery, automate processes, and ensure that equipment operates efficiently and safely. However, because they handle high voltages, complex circuitry, and integrated automation software, they also present a range of potential risks. Conducting a thorough risk assessment is therefore essential for anyone involved in the design, manufacture, or operation of these systems.

For experienced control panel manufacturers and system integrators, safety is not just about compliance with regulations but about protecting people, assets, and productivity.

Why does Control Panel Risk Assessment Matter?

A risk assessment is a structured process used to identify hazards, evaluate their likelihood and severity, and implement appropriate control measures. In the context of electrical control systems, this means considering how people interact with panels and machinery, what could go wrong, and how those risks can be reduced or eliminated.

Without a proper assessment, even a well-designed control system could expose operators to electrical shocks, arc flashes, or mechanical hazards. Faults such as short circuits or software errors can also lead to equipment damage or unexpected movement of connected machinery.

For this reason, industry standards such as BS EN 60204-1 and ISO 12100 provide detailed guidance on identifying and mitigating risks.

Identifying Potential Control Panel Hazards

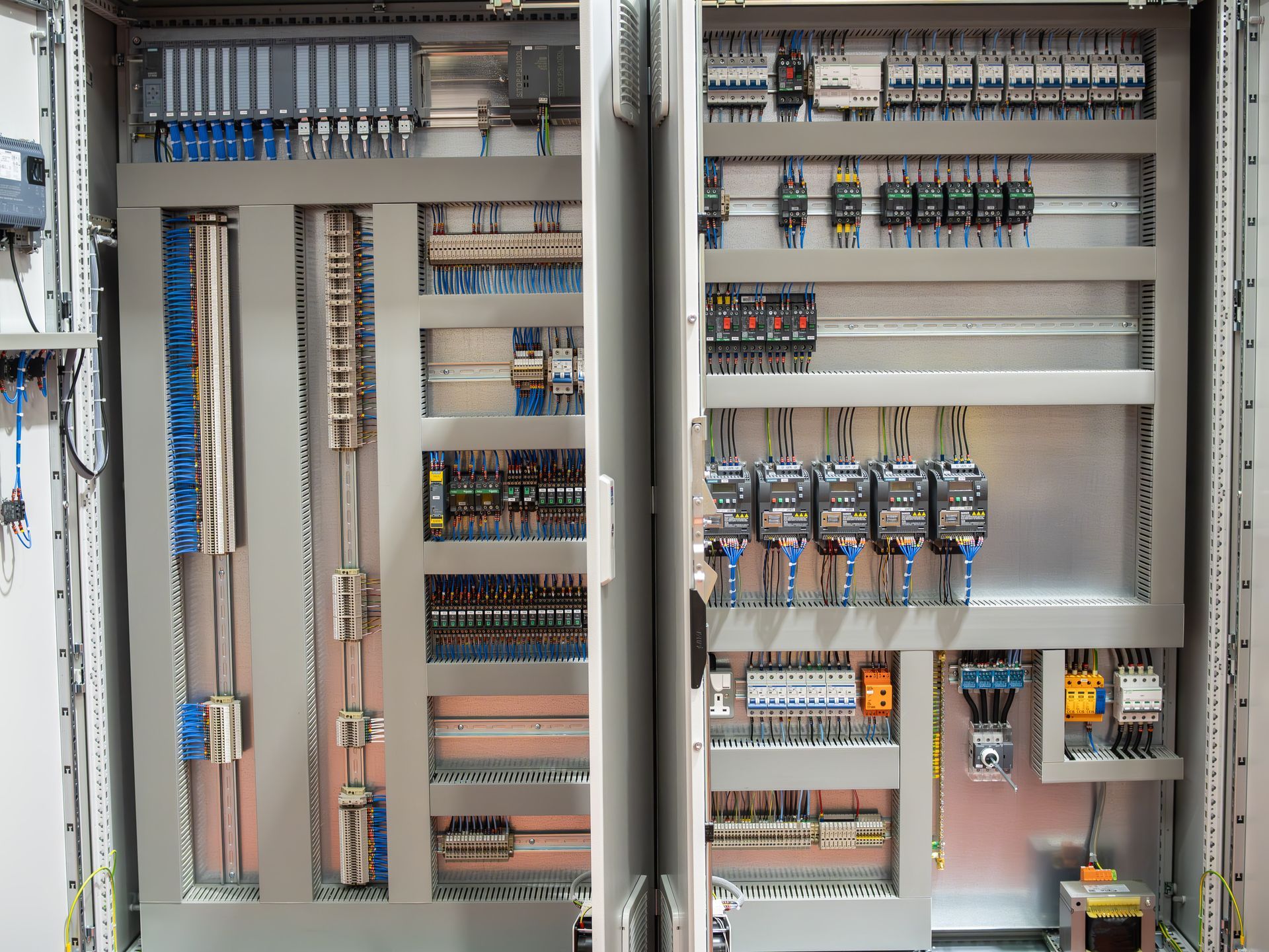

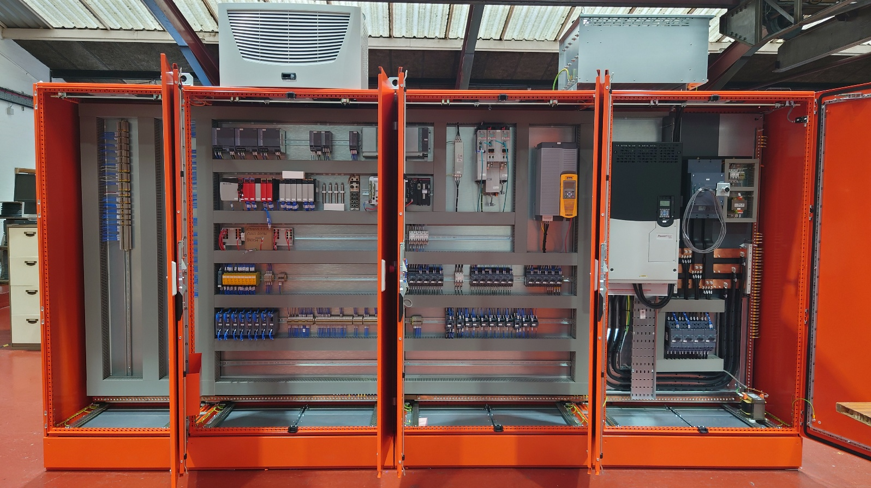

A risk assessment begins with identifying possible hazards. For a control panel builder, this involves examining every part of the system, from power supplies and wiring to sensors, actuators, and user interfaces. Common hazards include…

Electrical risks

exposed live parts, inadequate earthing, or incorrect cable sizing.

Mechanical risks

unexpected machine movement caused by control faults.

Thermal risks

overheating due to poor ventilation or overloading.

Human factors

improper use, poor labelling, or lack of emergency stop functions.

The assessor must also consider environmental factors, such as moisture, dust, vibration, or temperature, which can all affect electrical performance and safety.

Which Control Panel Risks Should be Prioritised?

Once hazards are identified, each is assessed based on two key factors: the likelihood of occurrence and the potential severity of harm. By combining these, engineers can prioritise which risks need immediate action and which can be monitored through regular maintenance.

For example, a control panel manufacturer may find that certain components are prone to overheating when installed in enclosed spaces. The risk can then be mitigated through better ventilation, thermal cut-offs, or revised component selection.

This stage of assessment should involve both engineers and operators, as those who use the equipment daily often have valuable insight into how it behaves under normal and abnormal conditions.

Implementing Control Panel Safety Measures

Risk reduction measures should follow a logical hierarchy. The first step is to eliminate the hazard wherever possible, for instance by designing the panel to avoid exposed live parts. If elimination is not possible, the next step is engineering control, which may include protective devices such as interlocks, emergency stops, or circuit breakers.

Administrative measures such as warning labels, safe operating procedures, and staff training also form an important part of the overall safety strategy. For a control panel builder, clear documentation and wiring diagrams are critical to ensure that maintenance staff and engineers can work safely in the future.

How Important is Review and Maintenance?

A risk assessment is not a one-off exercise. As systems are modified, upgraded, or moved to different environments, new hazards may emerge. Regular inspection and testing help confirm that safety devices and control logic continue to function as intended.

Routine maintenance, supported by accurate records, ensures that wear and tear do not lead to hidden electrical faults. Control panels that operate in demanding industrial settings may require more frequent assessment to keep up with changes in production processes or technology.

A comprehensive risk assessment forms the foundation of safe and reliable electrical control system design. It enables engineers and control panel manufacturers to identify potential hazards early, make informed design decisions, and maintain compliance with relevant standards.

For a control panel builder, embedding safety into every stage of the project, from design and installation to long-term maintenance, helps protect workers and equipment while ensuring consistent, trouble-free operation.