Are Bespoke Control Panels Worth It?

When businesses begin planning new machinery or upgrading existing systems, one of the biggest decisions they face is whether to invest in a bespoke control panel or choose an off the shelf alternative. At first glance, a standard panel may seem the simpler and more cost-effective option, but in many industries the long-term value of a tailored solution is far greater. Understanding what goes into control panel design and why so many companies turn to a specialist control panel builder can help determine which route offers the most benefit.

How are bespoke control panels built to match the application?

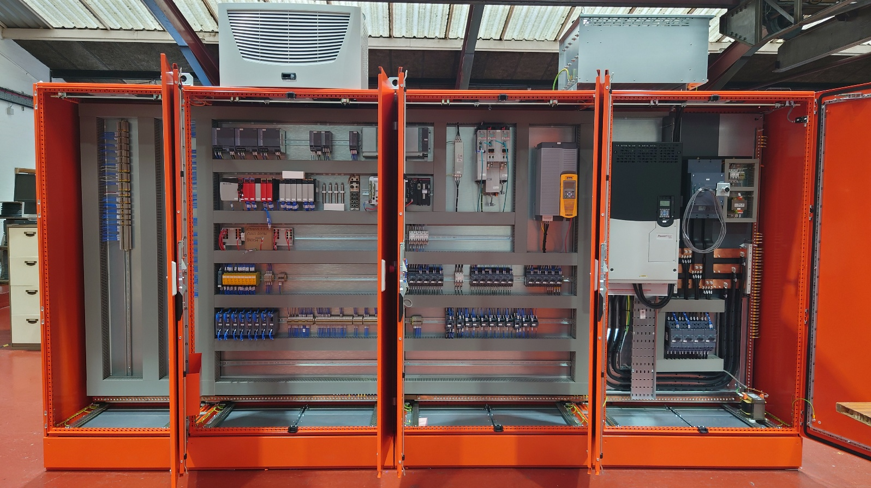

One of the strongest arguments for bespoke control panels is that they are created specifically for the job they need to perform. Every industrial process has its own unique demands, whether it involves complex automation, strict safety requirements, harsh environmental conditions, or the need for flexible inputs and outputs. Standard panels often require compromise, which can lead to inefficiency or additional components being added later.

A bespoke panel is designed around the machinery, the workflow, and the environment where it will operate. This level of precision ensures that the panel supports performance rather than limiting it. A skilled control panel builder can take detailed project requirements and deliver a system that integrates seamlessly with existing equipment.

Are bespoke control panels more reliable than standard options?

When a panel is designed for a specific application, the components, wiring layout, and safety features will all be chosen with the exact working conditions in mind. This often leads to improved reliability compared to more generic systems. For example, if a panel is installed in a dusty or high temperature environment, the designer can select enclosures, cooling systems, and protective features that ensure the panel remains stable over time.

Standard panels may not be able to cope with tough conditions or unusual load demands. Bespoke control panel design helps to avoid any unnecessary strain and reduce the likelihood of unplanned downtime, which can be far more costly than the upfront investment.

How do bespoke control panels make maintenance and troubleshooting easier?

Custom built panels are typically easier to maintain because they are laid out logically and documented thoroughly. When a panel is designed from scratch, the builder can position components for easy access, simplify cable routing, and include clear labelling. This makes servicing far quicker, which is valuable for businesses that cannot afford long periods of downtime.

A bespoke panel will also come with detailed wiring diagrams and documentation created specifically for that system. Engineers do not need to navigate generic manuals or guess how a standard panel has been adapted to fit the application. This clarity reduces maintenance errors and helps streamline future upgrades.

How bespoke panels provide greater adaptability

Industrial systems rarely stay the same forever. Processes evolve, equipment is updated, and new automation technologies become available. A bespoke control panel can be designed with potential expansion in mind, providing spare capacity or modular sections that support future additions.

Off the shelf panels often have limited room for upgrades, which means companies may end up replacing the entire unit earlier than expected. With a bespoke solution, a control panel builder can ensure the system has the flexibility to grow with the business.

How bespoke panel design promotes safety and compliance

Safety is a major factor in control system design. Bespoke panels can be built to meet the exact regulatory requirements of the industry, including specific electrical standards, machinery directives, and internal company policies. This ensures that equipment remains compliant and reduces the risk of safety incidents.

Standard panels might meet general regulations, but they may not include the precise safeguarding or monitoring features required for a particular machine. Custom control panel design allows businesses to incorporate dedicated safety relays, emergency stops, isolation points, and monitoring systems where they are needed most.

Are bespoke control panels worth the investment?

For businesses with simple or non-critical processes, a standard panel may be suitable. However, for companies that rely on automation, heavy machinery, or specialised processes, bespoke control panels offer clear advantages. They provide better performance, greater reliability, and long-term value that far outweighs the initial cost difference.

A panel built for purpose supports smoother operations and reduces the likelihood of breakdowns, saving both time and money over its lifespan. When considered this way, bespoke control panels are not just a purchase, but an investment in efficiency and future readiness.

FAQS

What makes bespoke control panels different from standard panels?

Bespoke control panels are designed specifically for the machinery, workflow, and environment in which they will operate. A tailored panel is built to meet the precise demands of the application, providing a better fit and more efficient performance.

Are bespoke control panels more reliable in challenging environments?

Yes. Because bespoke panels use components, layouts, and protective features chosen for the exact conditions they will face, such as heat, dust, or unusual load requirements, they typically offer greater reliability.

Do custom control panels make maintenance and troubleshooting easier?

A bespoke panel is usually easier to service due to its logical layout, accessible components, and clear labelling. It is also supplied with detailed, system-specific documentation and wiring diagrams.

Can bespoke control panels be adapted for future expansion?

Yes. Many modern industrial processes evolve over time, and bespoke control panels can be designed with flexibility in mind. Standard panels tend to offer far less room for expansion.

Are bespoke control panels worth the additional investment?

For simple applications, a standard panel may suffice. However, for businesses relying on heavy machinery, automation, or specialised processes, bespoke control panels provide superior long-term value.