Control Panel Solutions for the Food & Beverage Industry

The food and beverage industry depends on precision, safety, and efficiency. From automated bottling lines to temperature-controlled storage and packaging systems, electrical control panels play a crucial role in keeping operations running smoothly. Behind every modern production line sits a network of well-designed control systems that ensure processes are accurate, repeatable, and compliant with strict hygiene standards.

Working with experienced control panel manufacturers is vital for achieving this level of reliability and performance. The design and construction of these systems require detailed knowledge of both automation technology and the specific demands of food processing environments.

How do Control Panel Builders Ensure Food Safety & Hygiene?

In food and beverage production, hygiene and safety are non-negotiable. Equipment must be easy to clean, resistant to moisture, and built to prevent contamination. This extends to the electrical systems that control machinery. Panels installed in production areas are often exposed to humidity, temperature changes, and cleaning chemicals.

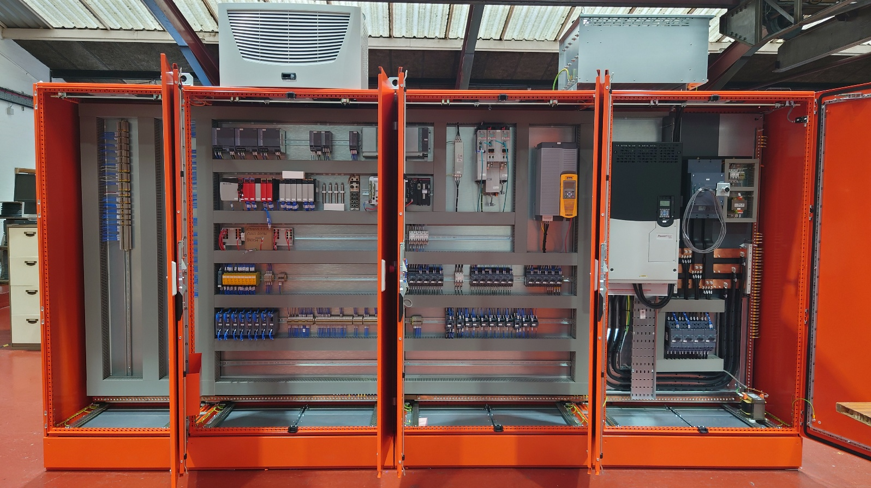

A skilled control panel builder designs enclosures that meet appropriate ingress protection ratings to keep out dust and water. Stainless steel is frequently used as it resists corrosion and can withstand regular washdowns. Cable entry points and seals are designed to maintain hygiene while ensuring electrical safety.

By combining robust construction with intelligent design, control panels help manufacturers meet food safety regulations while keeping equipment reliable and low-maintenance.

Precision and Process Control

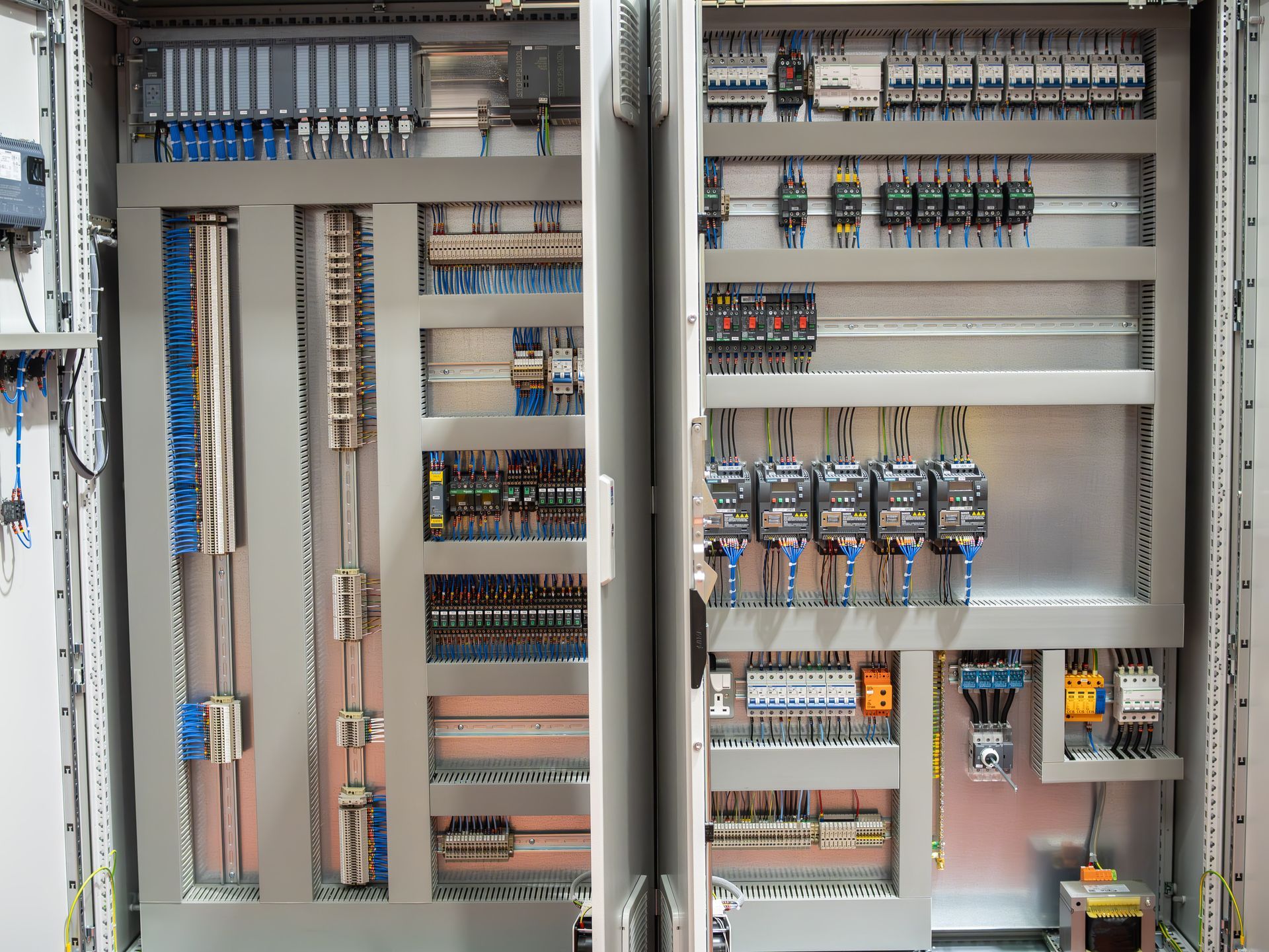

Automation is now at the heart of the food and beverage industry. From mixing and blending to filling, packaging, and labelling, processes rely on precise control to ensure consistent quality. Control panels serve as the communication hub between sensors, actuators, and machinery, allowing operators to monitor and adjust parameters such as temperature, pressure, and speed in real time.

Experienced control panel manufacturers incorporate programmable logic controllers (PLCs) and human–machine interfaces (HMIs) into their designs to simplify operation and data collection. These systems can record production data, monitor energy usage, and alert operators to potential issues before they cause downtime.

For example, in a bottling plant, a PLC-controlled panel can manage the flow of liquid, synchronise filling nozzles, and control capping mechanisms. Any deviation in pressure or timing is immediately detected and corrected, ensuring every product meets quality standards.

Supporting energy efficiency and sustainability

Energy consumption is a growing concern in food and beverage manufacturing, where refrigeration, heating, and automated machinery all contribute to high power use. Control panels can play an important role in improving energy efficiency.

Modern automation systems allow processes to be optimised by running equipment only when required and monitoring energy data to identify inefficiencies. Variable speed drives (VSDs), controlled through custom-built panels, can adjust motor speeds based on demand, significantly reducing energy waste.

A forward-thinking control panel builder will also consider future adaptability. As sustainability goals evolve, panels that are designed with flexibility in mind can accommodate new technologies such as renewable energy sources or advanced monitoring systems.

Compliance with industry standards

The food and beverage sector is heavily regulated, and control systems must comply with industry standards covering electrical safety, hygiene, and traceability. Well-established control panel manufacturers understand these requirements and design systems to meet CE marking, UKCA certification, and relevant ISO or HACCP standards.

Comprehensive documentation and testing are essential parts of the process. Panels are typically subjected to full functional testing before installation to ensure they perform exactly as intended. Once on-site, integration with existing systems is carried out carefully to minimise disruption to production.

Building reliability into every system

Reliability is the foundation of successful food production. Downtime in this sector can lead to costly waste and missed delivery schedules. Well-engineered control panels reduce the risk of faults and make maintenance simpler by providing clear labelling, accessible layouts, and built-in diagnostics.

By partnering with an experienced control panel builder, food and beverage companies can benefit from systems designed to perform reliably under the industry’s toughest conditions. The right control panel solution not only enhances safety and efficiency but also supports long-term growth and sustainability.